ShockWatch? 2 Impact Indicators

ShockWatch 2 Impact Indicators alert everyone that your shipment should be handled with care and that it is being monitored for mishandling. Our impact indicators have been shown to reduce damage by 40-60%.

Reduce costs without sacrificing quality.

Shipping docks are busy places with everyone rushing to get product shipped or received on time. Loading and unloading creates opportunities for products to get dropped and damaged. Carriers, manufacturers, and receivers are all impacted by damage-related costs. Often the question becomes who is responsible for the damage and where did the damage happen?

Damaged products benefit no one.

ShockWatch 2 indicators assist handlers in the supply chain refine their processes so the mishandling may be prevented. They help assign accountability when mishandling occurs. The goal of the ShockWatch program is to reduce damage related incidents and ultimately drive down costs.

ShockWatch 2 impact indicators indicate when products have been exposed to a potentially damaging impact during transit or in storage. ShockWatch devices are tamperproof, field-armable, mechanically-activated devices that turn bright red when an impact occurs. Their presence on shipments deters mishandling and results in reduced damage related costs.

Benefits:

? Acts as a visual deterrent to improper handling

? Reduces mishandling through awareness

? Provides indisputable evidence of mishandling

? Promotes chain of accountability for all product handling

? Confirms effectiveness of packaging

? Helps identify trouble spots in supply chain, from production to transportation and storage

? Helps increase quality of product from dock to dock

ShockWatch 2 in this photo is featured with a companion label and alert tape.

ShockWatch? 2 Impact Indicators

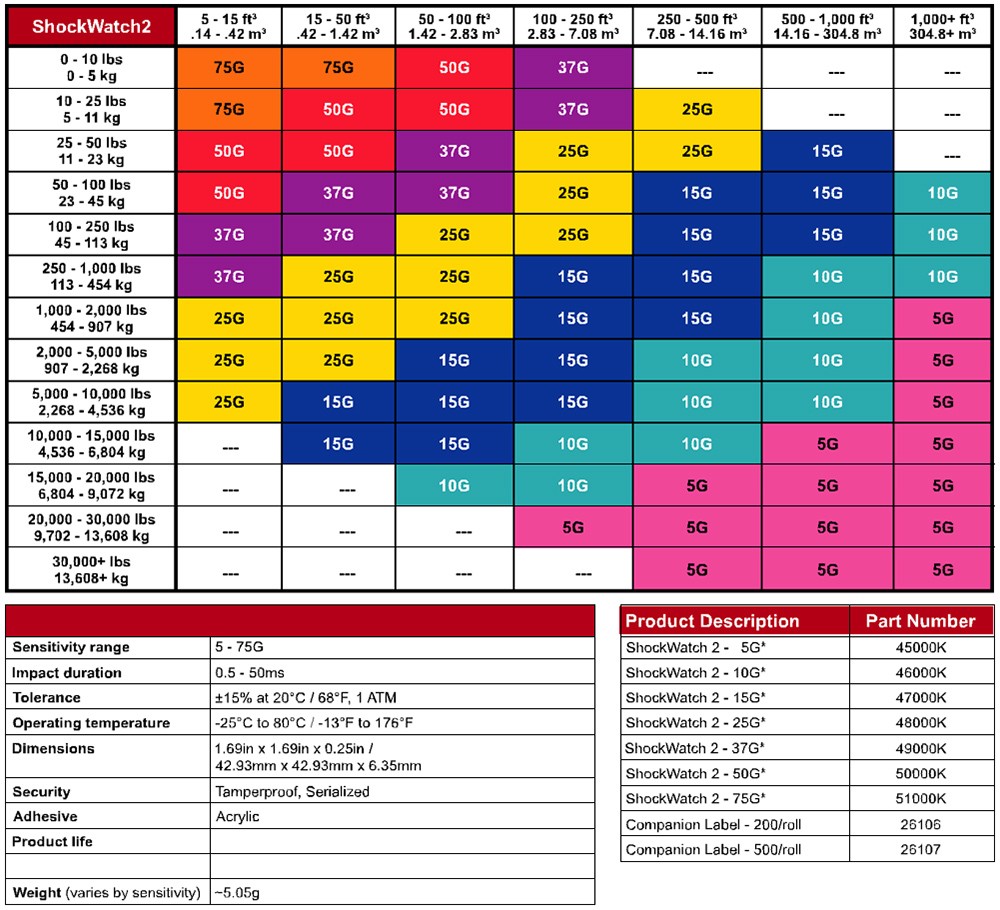

Selection Guide

Selecting the right indicator is a simple process. Start with your shipment size and weight. The selection guide provides a starting point for sensitivity selection. The indicator best suited to your application will also take into account product fragility and packaging. More fragile products may require a more sensitive (lower G) indicator while products with more robust packaging may need a less sensitive (higher G) indicator.